BioPoxy® 36

High Bio-Based Content Epoxy Laminating Resin

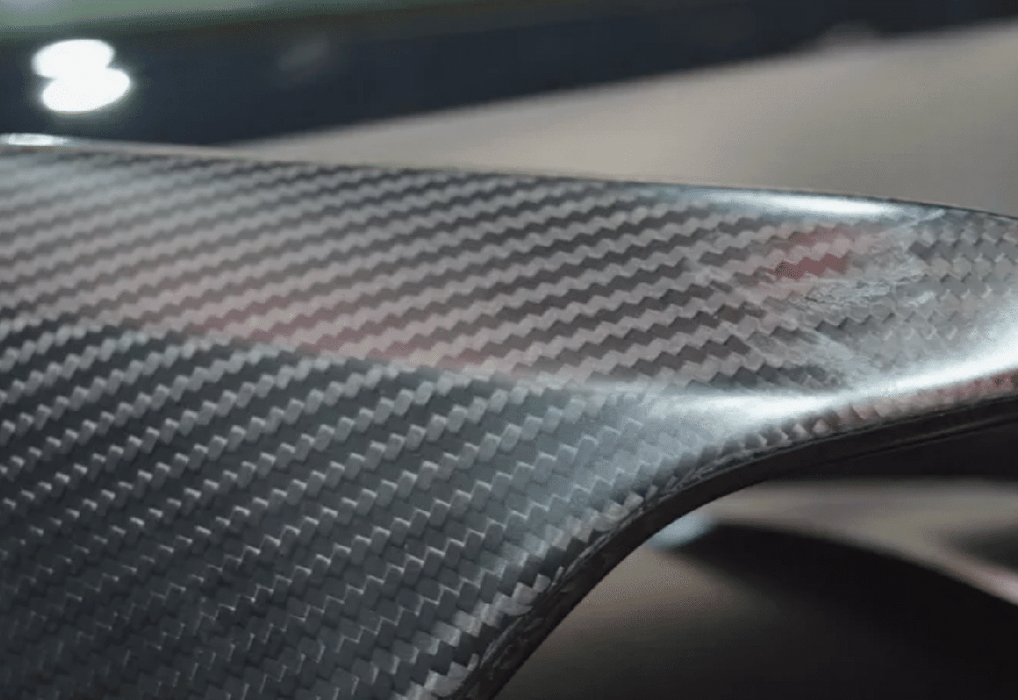

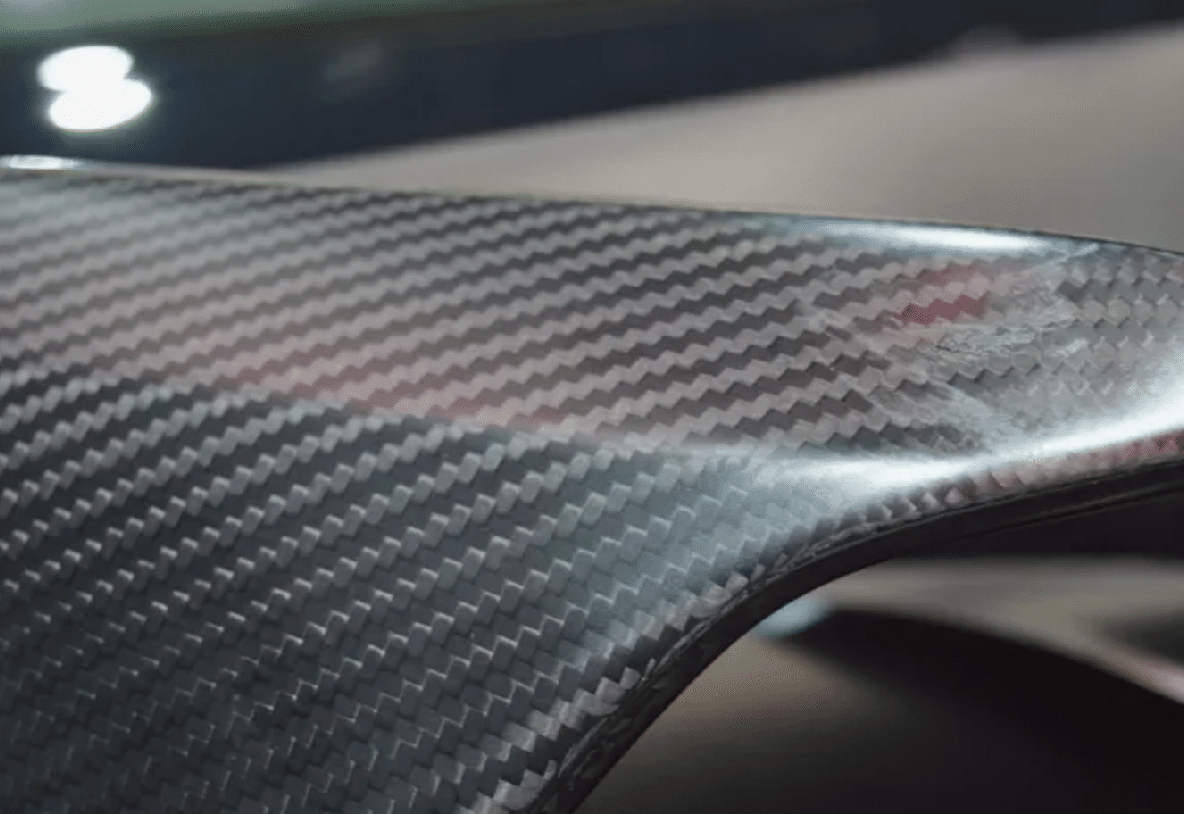

Developed For Composite Manufacturing

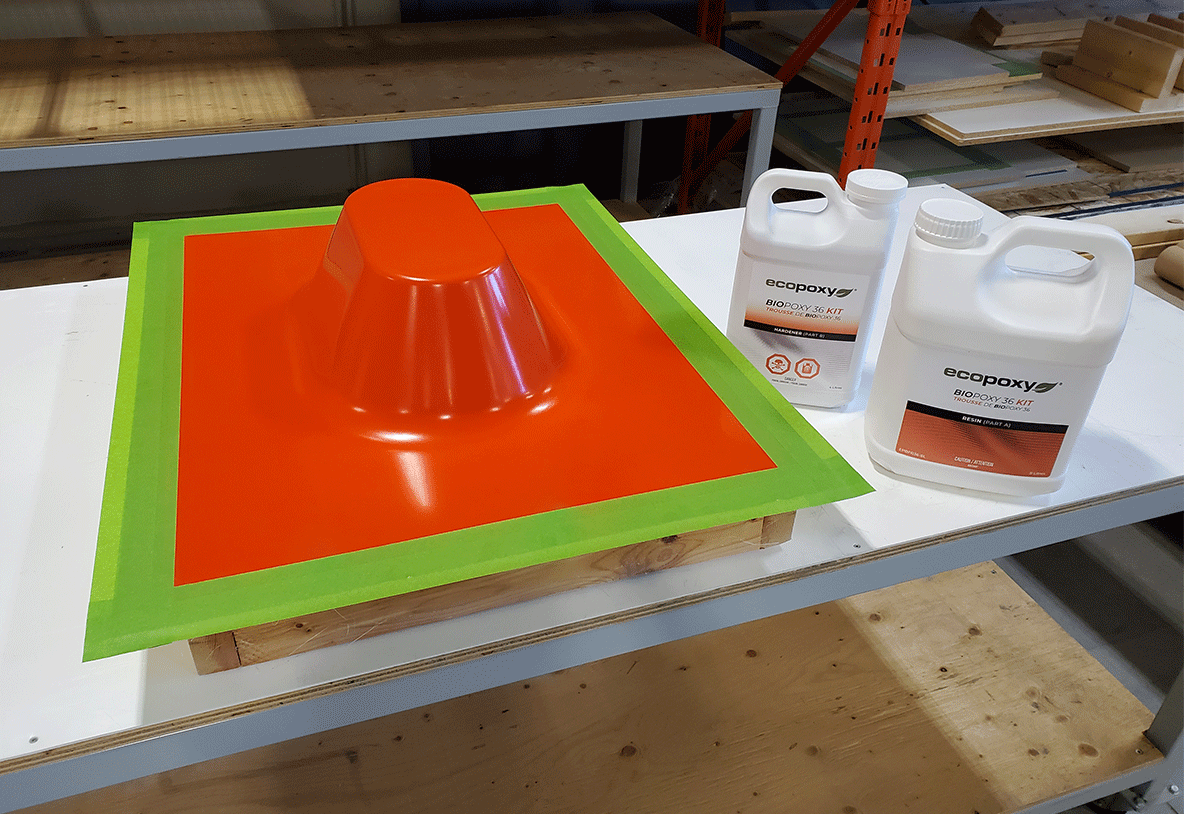

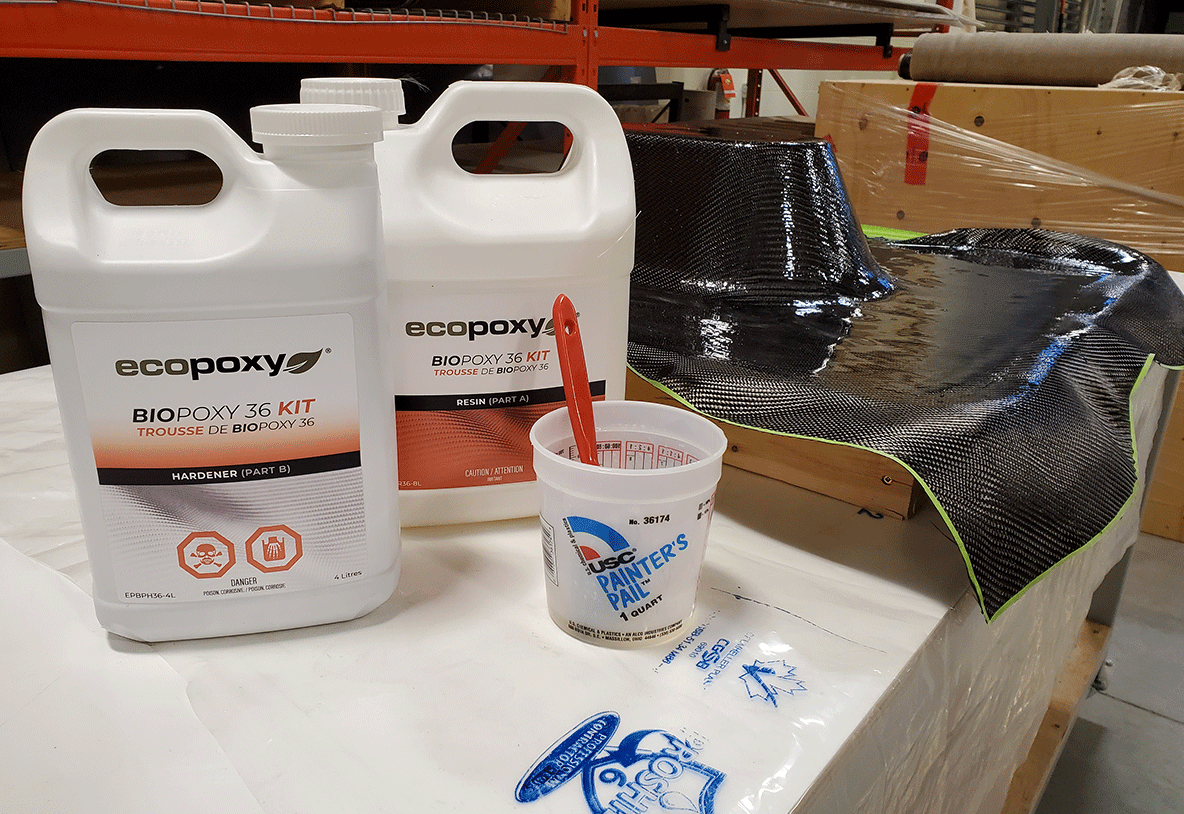

Ideal For Wet Layup & Wet Bagging

Excellent Wetting & Bonding of Fiber Reinforcements

Compatible with Carbon Fiber, Fiberglass, & Natural Fibers

High Bio-Based Content

Made with Annually Renewable Resources

Room Temperature Curing

Part of Ecopoxy’s User-friendly Laminating System